The textile industry generates large quantities of wastewater, containing high levels of dyes, chemicals, and suspended solids. Effective management of this wastewater is crucial for meeting environmental regulations and reducing the industry’s ecological footprint.

Membrane technologies offer a powerful solution for treating textile wastewater, providing high-quality effluent while minimizing water consumption and chemical use. This guide will help technicians understand various types of membrane technologies, their applications, and best practices for operation and maintenance.

CONTEXT

The importance of membrane technologies in textile wastewater treatment

Membrane technologies provide a precise and efficient solution for separating contaminants from the water.

By using selective barriers, membrane technologies effectively remove suspended solids, dissolved salts, and other impurities.

These filtration systems are especially attractive due to their ability to treat highly polluted wastewater with minimal chemical input. Reducing chemical dependency while saving water, these systems support the textile industry’s sustainability goals while ensuring compliance with environmental regulations.

Membrane filtration is anyway usually adopted after a well-designed effluent treatment plant and aims to further refine water quality to comply with stringent regulations.

METHODS

Types of membrane technologies for textile wastewater treatment

There are several types of membrane technologies available for treating textile wastewater, each suited to different needs based on the specific pollutants, treatment level, and operational efficiency.

Microfiltration (MF)

Microfiltration membranes have pore sizes ranging from 10 to 20 microns, making them effective at removing large particles, such as suspended solids, from wastewater. MF is commonly used as a pretreatment step to reduce solid loads before finer filtration processes.

- Applications: microfiltration is often used for initial filtration before ultrafiltration or when it is necessary to further improve water quality after an effluent treatment plant.

Ultrafiltration (UF)

Ultrafiltration membranes feature smaller pore sizes (0.04 to 0.10 microns), making them capable of removing larger organic molecules, colloidal particles, and proteins from wastewater. UF is suitable for retaining suspended solids and high-molecular-weight solutes.

- Applications: ultrafiltration can be used as a primary treatment or in combination with reverse osmosis or nanofiltration.

Nanofiltration (NF)

Nanofiltration is used to physically separate even extremely small soluble substances (ions, molecules) from an aqueous solution, with sizes measurable in nanometers (nm). Nanofiltration membranes are similar to reverse osmosis membranes but allow monovalent ions, undissociated acids, and very low molecular weight organic substances to permeate while retaining divalent ions and more complex organic substances.

NF provides effective pollutant removal with lower energy consumption.

- Applications: nanofiltration is ideal for color removal, treating high-concentration wastewater with dyes, and partial desalination.

Reverse osmosis (RO)

Reverse osmosis is one of the most advanced membrane filtration methods. With pore sizes smaller than 0.0001 microns, RO membranes remove dissolved salts, heavy metals, dyes, and nearly all organic compounds. RO produces the highest-quality effluent, making it an ideal solution for water reuse in textile manufacturing.

- Applications: RO is suitable for the production of ultra-pure water and for applications where treated water is reused in industrial processes.

FOCUS

Other advanced filtration technologies

In addition to the membrane technologies listed above, several advanced filtration methods are also available for treating textile wastewater. These include processes that can handle challenging pollutants like dyes, heavy metals, and organic compounds more effectively.

Here are some of the most notable:

- Activated charcoal (or activated carbon): a highly effective filtration method for removing a range of pollutants, including PFAS (per- and polyfluoroalkyl substances) and other organic contaminants. Activated charcoal works by adsorbing pollutants onto its porous surface, trapping chemicals as water passes through.

- Electrodialysis (ED): ED uses an electric field to separate ions, effectively desalinating high-salt textile wastewater. It’s energy-efficient at moderate salinities but works best for ionic pollutants and needs scaling maintenance.

- Membrane distillation (MD): MD separates water vapor from contaminants using a hydrophobic membrane, suitable for high-salinity wastewater. It can use low-grade heat sources, though it may have very high operational costs.

- Ceramic Membranes: these membranes are highly durable and chemically resistant, ideal for extreme pH or chemical-heavy textile wastewater. They’re longer-lasting but costlier upfront than polymeric membranes.

- Ion Exchange Membranes: ion exchange membranes selectively remove ions, making them useful for heavy metal removal in textile wastewater. They require regular regeneration, limiting their use with non-ionic pollutants.

ANALYSIS

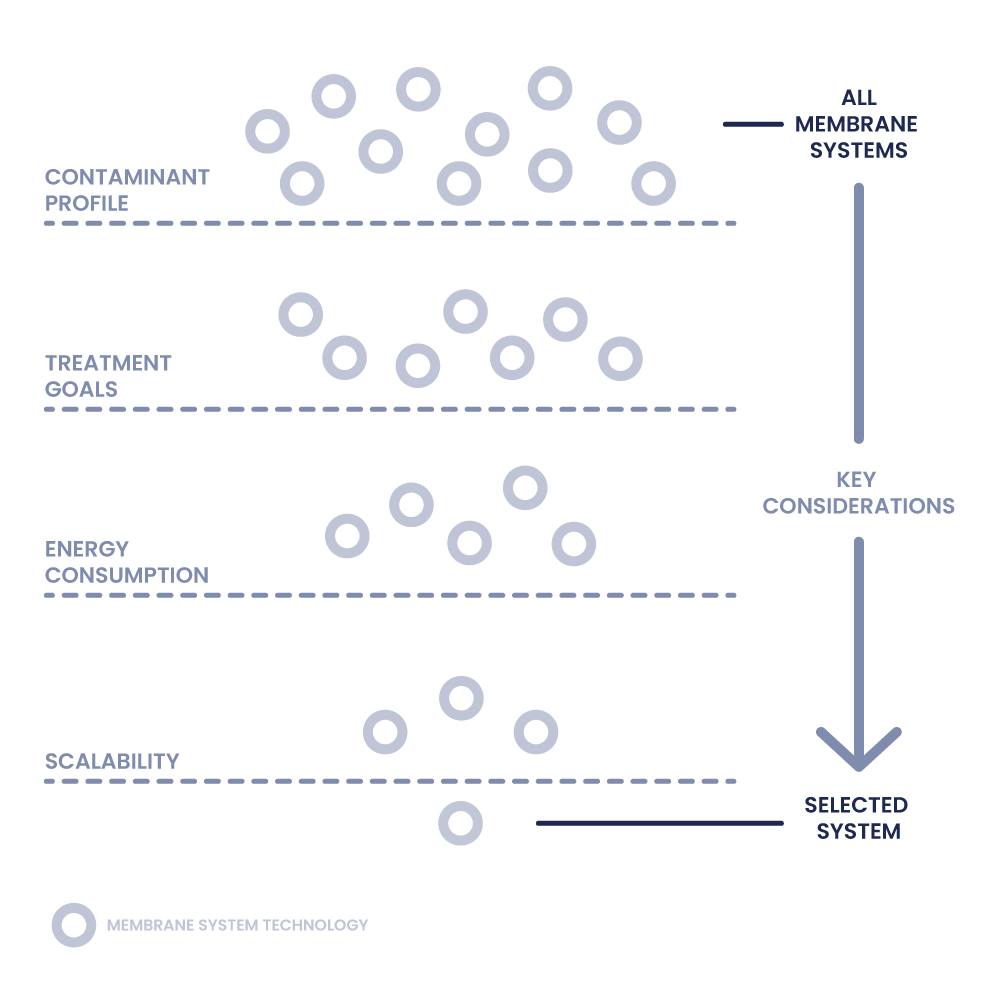

Key considerations for selecting membrane technologies

Technicians need to assess several factors when choosing membrane systems for textile wastewater treatment to ensure optimal performance and treatment results.

Contaminant profile

Understanding the makeup of the wastewater is critical. For example, wastewater with high levels of suspended solids may require microfiltration, while high concentrations of dyes and salts may call for reverse osmosis or nanofiltration.

Treatment goals

Clearly defining the treatment objectives is essential. Whether the goal is to reach a higher grade of water purity or achieve desalination will determine which membrane technology is most suitable.

Energy consumption

Membrane filtration, particularly reverse osmosis, can be energy-intensive. It is important to balance energy efficiency with treatment effectiveness. Selecting energy-efficient systems or optimizing operational parameters can reduce operational costs while maintaining high filtration standards.

Scalability

Production demands in the textile industry often fluctuate. Choosing a membrane system that can scale to handle variable flow rates and wastewater volumes is important for ensuring long-term flexibility and minimizing capital investment in retrofits.

FOCUS

Maintenance best practices for membrane systems

Proper maintenance is key to ensuring the longevity and performance of membrane systems. Technicians should follow these best practices to optimize system efficiency:

- Regular cleaning: membrane fouling is a common challenge. A consistent cleaning schedule using the right chemical agents will help remove organic and inorganic deposits, prolonging membrane life.

- Monitor system performance: continuous monitoring of pressure, flow rates, and water quality helps detect early signs of membrane fouling or performance degradation, allowing for timely interventions.

- Preventive maintenance: regular inspections of system components, such as pumps, valves, and sensors, help technicians identify potential issues before they cause system failures. Replacing worn-out parts and performing routine system audits is essential for smooth operation.

- Pretreatment: wastewater pretreatment, such as biological treatment with secondary sedimentation, reduces the load on membranes, minimizing fouling and enhancing overall system performance.

CONCLUSIONS

A correct strategy to choose the most efficient membrane system

Membrane technologies have become essential tools in managing textile wastewater. Technicians must understand the different types of membrane systems to select the most suitable solution for each unique wastewater treatment scenario.

Technicians can ensure optimal system performance by following best practices for membrane maintenance and considering the specific wastewater composition, treatment goals, and energy needs.