Efficient sludge management has evolved from a regulatory obligation into an opportunity for resource recovery and cost savings. Once viewed as a nuisance, sludge generated by wastewater treatment plants is now considered a valuable asset. By adopting modern sludge treatment technologies, industries can lower operating costs, recover energy, and contribute to sustainability goals.

This article explores industrial sludge, its origins, and advanced treatment methods to optimize operations while minimizing environmental impact.

CONTEXT

Turning waste into a resource: why sludge management matters

Industrial sludge is a natural byproduct of wastewater treatment, formed during processes like disintegration and settling. It contains organic and inorganic materials that concentrate pollutants, making it challenging to handle. Without proper treatment, sludge can harm ecosystems, pollute water sources, and pose serious health risks.

Advancements in sludge treatment technologies now allow industries to recover resources like biogas and agricultural nutrients, transforming waste into valuable outputs while meeting regulatory standards.

ANALYSIS

Understanding industrial sludge: sources and classification

Industrial sludge is semi-solid waste produced during wastewater treatment. Its composition depends on production processes, wastewater quality, and treatment methods. Major sources include:

- industrial systems: steel, aluminum, textile dyeing (link article 1), and food production facilities generate significant volumes;

- agriculture and livestock: farms produce nutrient-rich sludge that often requires stabilization;

- urban systems: residential wastewater and drainage maintenance contribute large quantities, especially during cleaning activities.

Industrial sludge is classified into three main types:

- biological sludge: derived from organic matter and suitable for processing into fertilizers for agricultural use;

- non-hazardous sludge: includes materials like plastics, metals, and glass; requires minimal treatment;

- hazardous sludge: contains harmful substances like heavy metals (e.g., mercury, lead) and needs specialized treatment to prevent environmental harm.

STRATEGIES

Best practices for efficient sludge management

Industries can improve sludge management by adopting these strategies:

- optimize pretreatment: effective pretreatment reduces sludge volume and enhances its quality, easing downstream processes. Techniques like chemical dosing and screening are particularly useful;

- monitor and automate systems: regular monitoring of sludge characteristics and automation of processes like dewatering ensure operational efficiency and reduce downtime;

- integrate energy recovery: technologies like anaerobic digestion convert sludge into biogas, lowering energy costs and environmental impact;

- minimize disposal costs: methods like thermal drying reduce sludge weight and volume, lowering transportation and disposal costs;

- ensure compliance: aligning practices with local environmental regulations protects ecosystems and avoids fines.

FOCUS

Key steps in sludge management

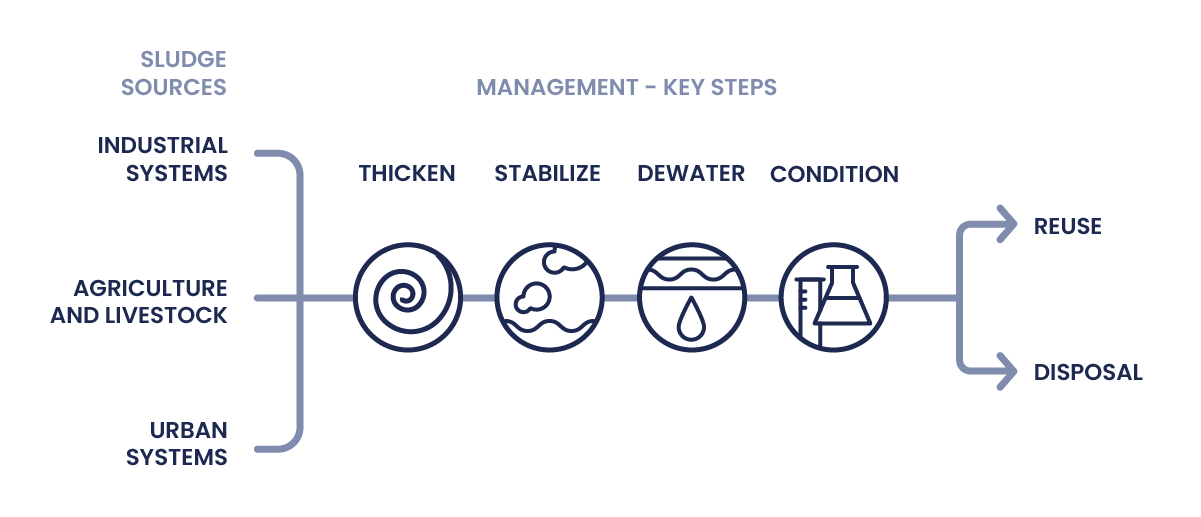

Efficient sludge management involves several stages aimed at reducing volume, improving handling, and ensuring safe disposal or reuse:

- thickening: increases solids content by removing excess water using techniques like gravity thickeners and centrifuges;

- stabilization: reduces organic content and odor using anaerobic digestion (producing biogas) or aerobic digestion;

- dewatering: removes additional water, turning sludge into a more solid form. Common technologies include belt filter presses and screw presses;

- conditioning: improves dewatering efficiency through chemical or thermal methods, altering the sludge structure;

- disposal or reuse: treated sludge can be disposed of in landfills, used as agricultural soil amendments, or incinerated for energy recovery.

SOLUTIONS

Top technologies for sludge treatment

Modern sludge treatment technologies enhance efficiency and resource recovery.

1. Centrifugal dewatering

High-speed rotation separates solids from liquids, producing drier sludge.

- PROS: high throughput, compact design.

- CONS: energy-intensive and requires regular maintenance.

2. Belt filter presses

These presses extract water from sludge using belts and pressure, producing a semi-solid cake.

- PROS: cost-effective for medium-scale operations.

- CONS: produces lower solids content than centrifuges.

3. Thermal drying

This technology uses heat to evaporate water from sludge, reducing its volume by up to 90%.

- PROS: enables easier disposal or reuse.

- CONS: high energy and capital costs.

4. Anaerobic digestion

Microorganisms break down organic matter, producing renewable biogas for electricity or heat generation.

- PROS: stabilizes sludge and reduces organic content.

- CONS: requires significant upfront investment.

INNOVATIONS IN SLUDGE MANAGEMENT TECHNOLOGIES

Three emerging technologies are advancing sludge management by offering sustainable solutions for resource recovery:

– hydrothermal carbonization (HTC): converts wet sludge into hydrochar, a coal-like material used as fuel or soil amendment. HTC operates at moderate temperatures and pressures, making it energy-efficient;

– sludge pyrolysis: heats sludge in the absence of oxygen, producing biochar, syngas, and bio-oil, which can be used for energy generation or as chemical feedstocks;

– sludge-based bioplastics: processes organic sludge components into bioplastics, providing a sustainable alternative to conventional plastics.

CONCLUSIONS

Industrial sludge management turns waste into a resource

Efficient sludge management is essential for industrial wastewater treatment, reducing costs and meeting environmental standards. By adopting advanced technologies, industries can optimize sludge handling while recovering valuable resources like energy and nutrients.

Coupled with best practices such as system monitoring, pretreatment optimization, and regulatory compliance, these methods empower industries to turn waste into a resource.