The textile industry’s high water usage and pollution load make Zero Liquid Discharge (ZLD) an important solution for achieving sustainable wastewater management. As a sustainability manager, implementing ZLD systems can help your company meet regulatory requirements, enhance water reuse, and improve corporate environmental performance.

This guide outlines the most effective ZLD technologies, practical implementation steps, and strategies for overcoming challenges in textile manufacturing.

CONTEXT

What is Zero Liquid Discharge (ZLD) and why does it matter?

As its name suggests, Zero Liquid Discharge (ZLD) refers to a comprehensive wastewater treatment approach that eliminates all liquid discharge by recycling and reusing water within industrial processes. By converting contaminants into solid waste for disposal or reuse, ZLD systems promote circularity, reduce freshwater intake, and ensure compliance with increasingly stringent environmental standards.

The textile industry, particularly during dyeing, bleaching, and finishing processes, generates large volumes of polluted wastewater. Implementing ZLD helps manufacturers meet requirements from initiatives like the ZDHC Programme, Bluesign®, and certifications such as ISO 14001.

ADVANTAGES

Quantifiable benefits of ZLD: building a business case for sustainability initiatives

For sustainability managers, justifying investments in ZLD requires a clear understanding of the tangible benefits:

- reduced water and wastewater treatment costs: lowering water purchase volumes and discharge fees;

- resource recovery potential: exploring the economic viability of recovering salts, water, and potentially other valuable byproducts;

- enhanced operational resilience: securing water supply in water-stressed regions, minimizing production disruptions;

- improved environmental performance metrics: achieving significant reductions in water footprint and pollution discharge, contributing to ESG goals and reporting;

- strengthened brand reputation and stakeholder engagement: demonstrating a commitment to environmental stewardship and meeting increasing demands for sustainable products.

Sustainability managers should focus on quantifying these benefits to build a strong internal business case for ZLD adoption.

ANALYSIS

Key technologies for achieving ZLD in textile factories

Achieving ZLD involves deploying a combination of technologies to capture, treat, and recycle wastewater. The most effective ZLD technologies include:

- membrane filtration (UF, NF, RO): advanced filtration methods like ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) remove suspended solids, salts, and chemicals. These processes are highly efficient for water purification and reuse.

- evaporation and crystallization: high-temperature systems that separate water from contaminants through evaporation, leaving solid residues for disposal or reuse. Effective for handling high-salinity wastewater.

- electrodialysis (ED): uses ion-selective membranes to separate and recover salts and other ions, ideal for desalination of textile wastewater.

- advanced oxidation processes (AOPs): techniques such as ozonation, UV, and Fenton’s reagent target persistent organic pollutants that conventional methods cannot break down.

- activated carbon filtration: Adsorbs organic pollutants and residual dyes, enhancing water quality before reuse.

FOCUS

Overcoming Challenges in ZLD Implementation

Implementing ZLD systems presents challenges that sustainability managers must address:

- high energy consumption: thermal processes like evaporation can be energy-intensive. Integrating renewable energy sources such as solar and wind can mitigate costs.

- capital investment: high upfront costs require clear ROI demonstration through improved efficiency, compliance, and sustainability benefits.

- scalability: systems must handle varying wastewater volumes without compromising efficiency.

- complexity of system integration and operation: emphasizing the need for skilled personnel and robust monitoring systems.

- solid waste management: developing sustainable strategies for the disposal or valorization of generated solid waste.

Strategic planning, continuous optimization, and leveraging technological advancements can help overcome these challenges.

SOLUTIONS

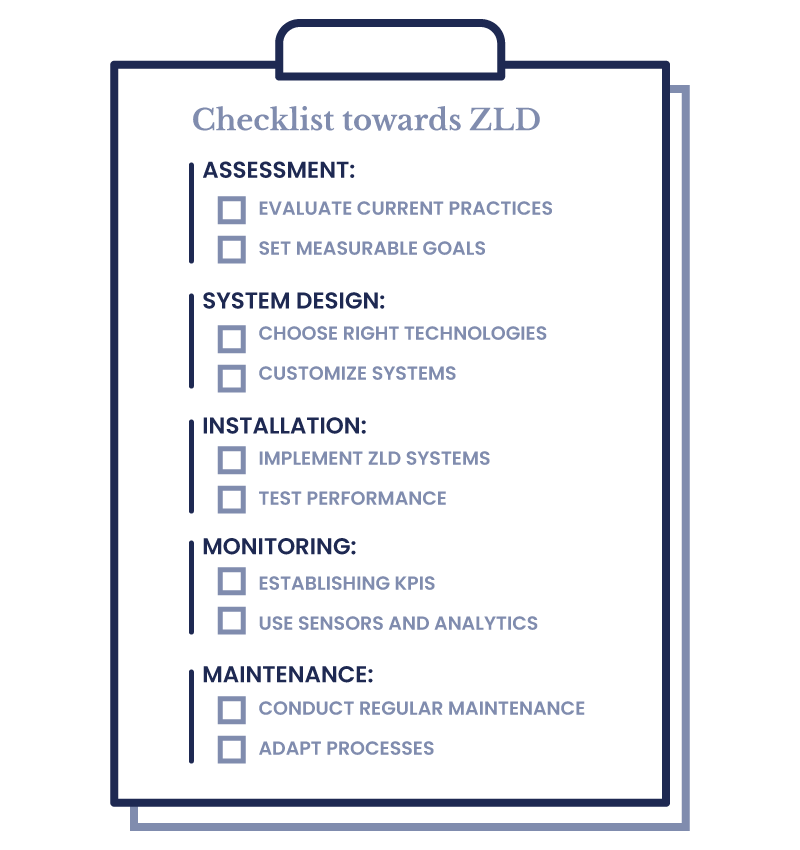

Implementing ZLD systems: a strategic approach

1. Assessment and Planning

- Evaluate current wastewater practices and identify pollution hotspots.

- Set measurable goals aligned with corporate sustainability frameworks (ISO 14001, ZDHC, GOTS).

2. System Design and Technology Selection

- Choose technologies based on wastewater composition, scale, and desired quality.

- Customize systems to address the specific needs of textile manufacturing.

3. Installation and Commissioning

- Implement ZLD systems with proper integration into existing infrastructure.

- Test performance against benchmarks and adjust as needed.

4. Monitoring and optimization

- Establishing key performance indicators (KPIs) to track water reuse rates, energy consumption, and waste generation.

- Use IoT-enabled sensors and AI-driven analytics to monitor performance and optimize processes.

5. Maintenance and continuous improvement

- Conduct regular maintenance and system audits to ensure efficiency and reliability.

- Adapt processes to meet evolving standards and sustainability targets.

FUTURE TRENDS IN ZLD FOR TEXTILE MANUFACTURING

Emerging technologies are making Zero Liquid Discharge (ZLD) systems increasingly efficient and cost-effective. AI-driven monitoring now enables predictive analytics, improving overall system performance and streamlining maintenance operations. At the same time, hybrid systems are gaining traction by combining multiple technologies to boost efficiency and reduce costs. Additionally, the integration of renewable energy sources is helping to power ZLD systems while lowering their carbon footprints. To stay competitive and meet evolving regulatory and sustainability standards, it is essential for sustainability managers to stay informed about these ongoing innovations.

CONCLUSIONS

Towards sustainable and cost-effective wastewater treatment

Implementing Zero Liquid Discharge (ZLD) systems can be a strategic advantage for textile manufactures. By investing in advanced technologies, designing tailored systems, and continuously optimizing processes, ZLD can significantly enhance their sustainability performance, ensure compliance, and achieve ambitious corporate environmental goals.

As regulations become stricter and consumer demand for eco-friendly practices grows, adopting ZLD systems can be an important solution for building a resilient, responsible, and profitable textile supply chain.